Features

For All Makes & Models (VAC-300 PSIG)

- Single Source for ALL your thermostatic trap elements

- Available for over 800 makes and models

- One-piece repair reduces maintenance time and aggravation. (In some instances a new cover is needed on the first installation only.

- No special tools are needed for installation

- The only repair element available today that is calibrated to ensure maximum sensitivity in the field

- Every element is factory tested, under live steam, before shipment to you

- Improves original trap’s performance with payback in fuel savings within weeks

- Over 80 years of repairing millions of steam traps

Description

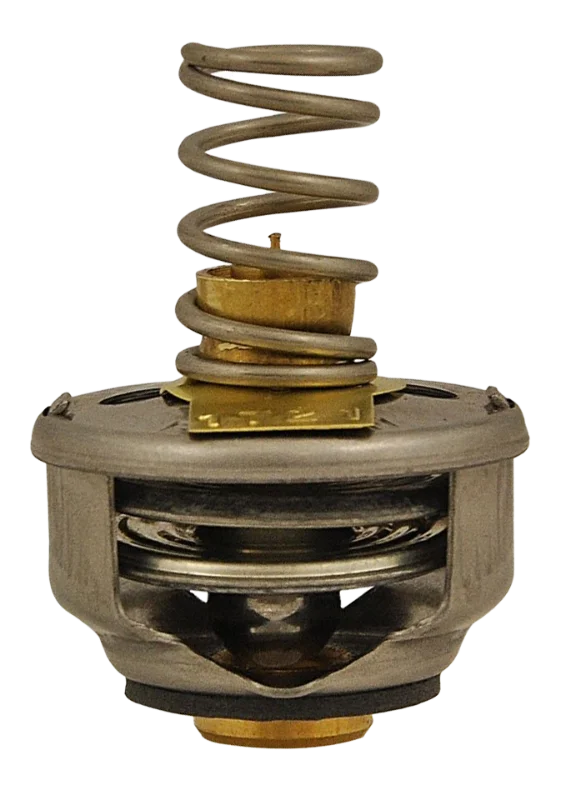

The Cage Unit compromises all working parts of a thermostatic steam trap including the seat. All parts are calibrated together under actual steam conditions at our factory and are locked into the precisely correct working relationship within a stainless steel housing. This is a one-piece, stand-alone, fully removable, and testable “trap within a trap”. There are no loose parts to contend with; gone is the potential of overtightening, under-tightening, cross-threading, or misaligning assorted pieces of a “repair kit”.

To the user, calibrated construction of a Barnes & Jones Cage Unit offers the assurance that every element will operate with the same performance in the field as it did when tested in our factory. This guarantees a greater sensitivity than could ever be promised with a bag of uncalibrated parts or any uncalibrated element.

Along with the fuel savings that accrue with the use of a more sensitive element, the Cage Unit offers increased efficiency with maintenance as well. The one-piece construction allows for the removal and testing of the element outside of the original trap body.

Adaptions of the Cage Unit are available for more than 800 makes, styles, and sizes of thermostatic steam traps for low, medium, and high-pressure service. Even if your system consists of traps from Dunham-Bush, Hoffman, Nicholson, Sarco, Warren-Webster, or any other brands, Barnes & Jones Cage Units can repair them all! Ask for or consult the “Steam Trap Repair Guide” to find the Cage Unit specifically designed to upgrade the working parts in your particular steam trap.

DO NOT be fooled by others offering a quick fix with nuggets, capsules, discs, or other control devices for steam traps. Barnes & Jones has been repairing thermostatic and float & thermostatic steam traps for over 80 years and is the acknowledged leader in product performance and design.

Operation

A faulty steam trap can …

- waste valuable heating $$$

- destroy condensate pumps

- create hot and cold spots within a heating zone

- cause production inefficiency of process equipment

- produce destructive water hammer

- lead to undue wear on, and premature failure of, other traps

Common Methods of Checking Traps

Some people feel that a hot return line from the trap indicates a leak. Others listen to the trap for a telltale whistle. Neither method is practical! A trap that is cycling properly will discharge condensate near saturated steam temperature. Obviously, the return line will be hot also. In a closed system, piping will carry noises for long distances. With several traps in the vicinity, listening will not always pinpoint the specific trap that is bad.

Observing the discharge from the traps is the only positive way of checking the operation of a steam trap! Only then can you determine whether the trap is cycling properly and if it closes tightly. To do this in a closed system it is necessary to valve the discharge at each trap so that the discharge from that trap is isolated from the rest of the system and the condensate can be dumped into the atmosphere from the trap body. It is of course a more costly installation but worth the added cost in the long run. Traps installed outdoors generally discharge to the atmosphere and their operation can be observed readily.

If it is deemed too costly or is physically impossible to valve the discharge of every trap, the only possible way to check the trap operation (unless you use Barnes & Jones traps or Cage Units) is to remove each trap, mount it on a test rack and observe the operation. This can be time-consuming and costly, perhaps as costly as forgetting preventative maintenance and simply waiting for each trap to fail badly before repairing it.

B&J Makes Trap Checking Easy

The Barnes & Jones thermostatic trap or any make of thermostatic trap with a B & J Cage Unit interior can, however, be easily and accurately tested by periodically replacing the Cage Unit. Then the Cage Units that have been removed can be tested in a representative trap body that has been attached to a steam line.

This can be done with complete accuracy as each Cage Unit operates independently and the trap body acts solely as a housing. This is not possible to do with other manufacturers’ elements whose performance is dependent upon the relationship of a screwed-in seat, element, lock washer, and cover with the original trap body. The Cage Unit combines all these parts in an unalterable working relationship.

Construction

Literature

A – Diaphragm B – Bronze Bellows C – Monel Bellows (sm) D – Monel Bellows (med) * = A new cover is required the first time a Barnes & Jones Cage Unit is used.

| Unit | Type | Unit | Type | Unit | Type | Unit | Type | Unit | Type | Unit | Type | Unit | Type | Unit | Type | Unit | Type | |

| 101X | B | 2155 | A | 3034* | A | 3338 | A | 3546* | A | 4063 | A | 4192* | A | 4309 | C | 4419 | A | |

| 159P | A | 2157 | A | 3035 | B | 3339 | B | 3547 | B | 4064 | A | 4193 | A | 4310 | A | 4422 | B | |

| 159X | B | 2159 | A | 3036 | A | 3354 | A | 3548 | A | 4066* | A | 4194 | A | 4311* | A | 4424 | B | |

| 1721 | A | 2161* | A | 3039 | B | 3355 | B | 3549* | A | 4067 | B | 4195 | A | 4312 | D | 4425 | A | |

| 1722 | A | 2162 | A | 3046 | A | 3368 | A | 3551 | A | 4069 | A | 4196 | A | 4314* | C | 4427 | B | |

| 1730 | A | 2163* | A | 3047* | A | 3375 | A | 3553 | A | 4070 | A | 4197* | A | 4315* | A | 4428 | A | |

| 1733 | A | 2164* | A | 3053 | A | 3376 | A | 3554 | B | 4072 | A | 4198 | A | 4316 | A | 4430 | B | |

| 1748 | A | 2166* | A | 3054 | A | 3379* | A | 3555* | A | 4073 | A | 4199* | A | 4317 | A | 4436 | C | |

| 1750 | A | 2167 | A | 3059* | B | 3380 | A | 3556* | A | 4075* | A | 4200 | A | 4318 | C | 4440 | A | |

| 1751 | B | 2168 | A | 3066* | A | 3381 | A | 3557 | B | 4076 | A | 4201 | A | 4319 | A | 4441 | A | |

| 1757 | C | 2171 | A | 3071 | A | 3384* | A | 3559* | A | 4077 | A | 4202* | A | 4320* | C | 4442 | A | |

| 1760 | A | 2173 | A | 3072 | A | 3387 | A | 3560* | A | 4078 | A | 4203* | A | 4321* | A | 4443 | C | |

| 1762* | A | 2175 | A | 3073 | A | 3393 | A | 3561 | A | 4079 | A | 4204 | A | 4322* | A | 4444 | C | |

| 1764 | A | 2176 | A | 3083 | A | 3395* | A | 3562 | A | 4080 | A | 4205 | A | 4323 | A | 4445 | A | |

| 1767* | A | 2177 | A | 3084 | A | 3396 | A | 3563 | A | 4081 | A | 4206 | A | 4324 | A | 4500 | B | |

| 1775 | A | 2182 | B | 3085 | A | 3397 | A | 3565 | A | 4082* | A | 4207 | A | 4325 | A | 4999 | A | |

| 1781 | A | 2188 | A | 3087 | A | 3398 | A | 3566* | A | 4083 | A | 4208 | A | 4326 | A | 5000* | A | |

| 1783 | A | 2189 | A | 3092 | A | 3399 | A | 3567* | A | 4084 | A | 4209* | A | 4327 | B | 5001 | A | |

| 1785 | A | 2192* | B | 3093* | A | 3400 | A | 3568* | A | 4085 | A | 4210 | A | 4328 | B | 5002 | A | |

| 1794 | B | 2193 | A | 3095 | A | 3401 | A | 3569* | A | 4086 | B | 4213 | D | 4329 | A | 5005 | A | |

| 1797* | A | 2194 | A | 3097* | A | 3402* | A | 3570 | A | 4087* | A | 4214 | D | 4330 | C | 5006 | A | |

| 1915 | A | 2198 | A | 3099* | A | 3407* | A | 3571* | A | 4088 | A | 4215 | A | 4331 | B | 5007 | A | |

| 1927* | A | 2200 | A | 3100* | A | 3409* | A | 3572* | A | 4089 | A | 4216* | A | 4332 | B | |||

| 1929 | A | 2203 | A | 3103* | A | 3410 | A | 3573* | A | 4090 | B | 4217 | D | 4333 | C | |||

| 1930* | A | 2205 | B | 3105 | A | 3413 | B | 3575* | A | 4091 | A | 4218 | A | 4334 | A | |||

| 1932 | B | 2208 | A | 3107* | A | 3414 | A | 3576* | A | 4093* | B | 4219* | A | 4335 | A | |||

| 1935 | A | 2211 | A | 3108* | A | 3417 | A | 3577* | A | 4096 | A | 4220* | A | 4336 | B | |||

| 1940 | A | 2212 | A | 3110 | B | 3419 | A | 3578* | A | 4097 | A | 4221 | A | 4337 | B | |||

| 1950* | A | 2213 | A | 3111 | A | 3420 | A | 3579* | A | 4098 | A | 4222 | A | 4338 | B | |||

| 1952 | A | 2214 | A | 3115* | A | 3421* | A | 3580 | A | 4100* | A | 4223 | A | 4339* | B | |||

| 1955 | A | 2215 | A | 3116 | A | 3427* | A | 3581* | A | 4102 | A | 4224* | B | 4340* | B | |||

| 1964* | A | 2217 | A | 3118* | A | 3429* | A | 3582* | A | 4105 | A | 4225 | A | 4341* | B | |||

| 1965 | A | 2218 | A | 3119* | A | 3430 | A | 3584* | A | 4106 | A | 4226* | A | 4342 | A | |||

| 1966 | A | 2220 | A | 3125 | A | 3431 | A | 3586 | A | 4107 | A | 4227* | A | 4343* | B | |||

| 1967 | A | 2226 | A | 3128 | A | 3433 | A | 3587 | A | 4109* | A | 4230* | A | 4344 | C | |||

| 1968 | A | 2230 | A | 3133* | A | 3434* | A | 3588* | A | 4110 | A | 4231 | A | 4345 | C | |||

| 1969 | A | 2231 | A | 3141 | A | 3435* | A | 3589 | A | 4111* | A | 4232 | A | 4346* | A | |||

| 1971* | A | 2244* | A | 3142 | A | 3436 | A | 3590* | A | 4112 | A | 4233* | A | 4347 | B | |||

| 1972 | A | 2245 | B | 3143 | A | 3437 | A | 3591 | A | 4113* | A | 4235 | A | 4348* | B | |||

| 1973* | A | 2250 | A | 3145 | B | 3438 | A | 3592* | A | 4114 | A | 4236 | A | 4349* | B | |||

| 1974* | A | 2253* | A | 3146 | A | 3439 | A | 3593 | A | 4115 | A | 4237 | A | 4350* | A | |||

| 1979 | B | 2261* | A | 3147 | A | 3440* | A | 3594 | A | 4116 | A | 4238 | B | 4351 | B | |||

| 1980 | B | 2272* | A | 3150 | A | 3442 | A | 3595 | A | 4117 | A | 4240 | A | 4352 | C | |||

| 1981 | C | 2779 | B | 3151* | A | 3444 | A | 3596* | A | 4118 | A | 4241 | A | 4353 | B | |||

| 1982 | B | 2781 | B | 3152* | A | 3445 | A | 3597* | A | 4119* | A | 4242 | B | 4354 | B | |||

| 1985 | A | 2790 | A | 3153* | A | 3446 | A | 3598* | A | 4120 | A | 4243 | A | 4355 | B | |||

| 1990* | A | 2791 | A | 3155 | A | 3447* | A | 3632 | A | 4121 | A | 4244 | A | 4356 | A | |||

| 1991 | B | 2793 | A | 3158 | A | 3448* | A | 3795 | D | 4122 | B | 4245* | B | 4357 | A | |||

| 1992 | A | 2805 | A | 3159 | A | 3449* | B | 3813 | B | 4124* | A | 4246 | A | 4358 | D | |||

| 1993 | A | 2806* | A | 3163* | A | 3460* | A | 3834 | C | 4125* | A | 4247 | A | 4359* | B | |||

| 1997 | A | 2808 | A | 3165 | A | 3461 | A | 4001 | A | 4126 | A | 4248* | A | 4360 | B | |||

| 1998 | A | 2813 | A | 3166 | A | 3465* | A | 4002 | A | 4127* | A | 4249 | B | 4361 | A | |||

| 2000* | B | 2814 | A | 3167 | A | 3466* | A | 4003 | A | 4128 | A | 4250 | A | 4362 | A | |||

| 2001* | A | 2815 | A | 3168 | A | 3467* | A | 4005 | A | 4129 | A | 4251 | A | 4363 | C | |||

| 2002* | B | 2818* | A | 3170 | A | 3470* | A | 4006 | A | 4130 | A | 4252 | A | 4364* | C | |||

| 2003* | B | 2819 | A | 3172 | A | 3472 | A | 4008 | A | 4131 | A | 4253* | C | 4365 | B | |||

| 2005* | A | 2823 | A | 3174* | A | 3475* | A | 4009* | A | 4133* | A | 4254 | C | 4366 | B | |||

| 2007 | A | 2825 | A | 3176* | A | 3476* | A | 4010* | A | 4134 | A | 4255 | C | 4367 | B | |||

| 2020 | A | 2826* | A | 3178 | A | 3479 | A | 4012* | A | 4135 | A | 4256 | A | 4368 | B | |||

| 2021 | A | 2830 | A | 3196 | A | 3481 | A | 4013 | A | 4137 | A | 4257* | C | 4369* | B | |||

| 2022 | A | 2835 | A | 3197* | A | 3484 | A | 4014* | A | 4138* | A | 4258 | C | 4370 | B | |||

| 2023 | B | 2836* | A | 3199 | A | 3487* | A | 4015* | A | 4139 | A | 4259 | A | 4371 | C | |||

| 2031* | A | 2840 | A | 3206 | A | 3488 | A | 4016 | A | 4140 | B | 4260 | C | 4372 | B | |||

| 2032* | A | 2849* | A | 3209* | A | 3489* | B | 4017* | A | 4141 | A | 4261 | C | 4373 | B | |||

| 2034 | A | 2850* | B | 3217 | A | 3490 | A | 4018* | A | 4142* | A | 4263* | C | 4374* | B | |||

| 2035 | A | 2852 | A | 3219* | A | 3491 | A | 4019 | A | 4143* | A | 4264 | C | 4375 | B | |||

| 2041 | B | 2854 | A | 3224 | A | 3493 | A | 4020* | A | 4144 | A | 4265 | C | 4376 | B | |||

| 2043* | A | 2857 | B | 3225* | A | 3494 | A | 4021 | A | 4145* | A | 4266* | A | 4377* | B | |||

| 2045 | A | 2863 | A | 3228 | A | 3495 | A | 4022 | A | 4146 | A | 4267* | A | 4378 | B | |||

| 2051* | A | 2864 | A | 3229 | A | 3496 | A | 4023 | A | 4147* | A | 4268* | C | 4379 | B | |||

| 2052* | A | 2865 | A | 3230* | A | 3497* | A | 4024* | A | 4148* | A | 4269* | A | 4380 | A | |||

| 2053 | B | 2866 | B | 3231* | A | 3499 | A | 4025* | A | 4149 | A | 4270 | B | 4381 | B | |||

| 2054 | B | 2879 | A | 3232* | A | 3500 | A | 4026 | A | 4150 | A | 4271 | B | 4382* | A | |||

| 2063 | A | 2880 | A | 3234 | A | 3501* | A | 4027 | A | 4151 | A | 4272 | B | 4383 | B | |||

| 2065 | B | 2881* | A | 3238 | A | 3502 | A | 4028* | A | 4152 | A | 4273 | A | 4384* | B | |||

| 2066* | A | 2884* | A | 3242 | A | 3503* | A | 4029 | A | 4153 | A | 4274 | C | 4385* | A | |||

| 2068* | A | 2885 | A | 3244 | A | 3504 | A | 4030* | A | 4154* | A | 4276 | B | 4386 | B | |||

| 2074* | A | 2896* | A | 3246 | A | 3506 | A | 4031 | A | 4156 | A | 4277 | B | 4387* | B | |||

| 2075 | A | 2897 | A | 3247* | A | 3507 | A | 4032* | A | 4157* | A | 4278* | B | 4388 | A | |||

| 2078 | A | 2901* | A | 3251 | A | 3508 | A | 4033* | A | 4158 | A | 4279* | C | 4389 | B | |||

| 2080* | A | 2907* | A | 3263 | A | 3509 | A | 4034* | A | 4159 | A | 4280* | A | 4391 | A | |||

| 2081 | A | 2911* | A | 3266 | A | 3510 | A | 4035* | A | 4160 | A | 4281 | A | 4392 | C | |||

| 2085 | A | 2924 | B | 3267 | A | 3511 | A | 4036 | A | 4161 | A | 4282* | A | 4393 | B | |||

| 2086* | A | 2926* | A | 3268 | A | 3513 | A | 4037 | A | 4162 | C | 4283 | A | 4394 | A | |||

| 2087 | A | 2929* | A | 3271 | A | 3514 | A | 4038 | A | 4163 | A | 4284* | A | 4395 | C | |||

| 2088 | B | 2931* | A | 3275* | A | 3515 | A | 4039* | A | 4164 | D | 4285 | A | 4396 | A | |||

| 2095 | A | 2947 | A | 3276 | B | 3516 | B | 4040 | B | 4165 | C | 4286* | C | 4397 | B | |||

| 2098 | A | 2948 | A | 3279 | A | 3517 | A | 4041 | A | 4166 | D | 4288 | A | 4398* | B | |||

| 2103 | B | 2952 | A | 3282 | A | 3520 | A | 4042 | A | 4167 | D | 4289 | B | 4399* | A | |||

| 2104 | A | 2953* | A | 3284 | A | 3522 | B | 4043* | A | 4168* | A | 4290 | A | 4400 | B | |||

| 2106 | A | 2958 | A | 3288* | A | 3523 | A | 4044* | A | 4169* | A | 4291 | C | 4402 | B | |||

| 2109 | A | 2959* | A | 3294 | A | 3524* | A | 4045 | A | 4170 | D | 4292* | B | 4403* | A | |||

| 2110 | A | 2961 | A | 3297* | A | 3525 | A | 4047 | A | 4171 | A | 4293 | A | 4404 | A | |||

| 2114 | A | 2964 | A | 3299 | A | 3526* | A | 4048* | A | 4172* | A | 4294 | C | 4405* | B | |||

| 2117 | A | 2983 | A | 3298 | A | 3527* | A | 4049* | A | 4173 | A | 4295 | A | 4406* | B | |||

| 2118 | A | 2987 | A | 3300 | A | 3528 | B | 4050 | A | 4175 | B | 4296 | A | 4407 | B | |||

| 2123* | A | 3012* | A | 3306 | A | 3529 | A | 4051 | A | 4176 | D | 4297 | A | 4408 | B | |||

| 2124 | A | 3015* | A | 3311 | A | 3530 | A | 4052 | A | 4177 | A | 4298 | A | 4409 | A | |||

| 2132 | A | 3016 | A | 3313* | A | 3531 | A | 4053 | A | 4178 | A | 4299* | B | 4410 | B | |||

| 2134* | A | 3019 | A | 3314 | A | 3532 | A | 4054 | A | 4179 | A | 4301 | A | 4411 | C | |||

| 2136* | A | 3020* | B | 3325 | A | 3533 | A | 4055* | A | 4181 | A | 4302 | A | 4412* | A | |||

| 2137 | A | 3021 | A | 3329 | A | 3534 | A | 4057 | B | 4182 | A | 4303 | C | 4413 | B | |||

| 2147 | A | 3022* | A | 3333* | A | 3536 | A | 4058* | A | 4186 | A | 4304 | A | 4414* | A | |||

| 2148 | A | 3023 | A | 3334* | A | 3537 | A | 4059* | A | 4187* | A | 4305 | A | 4415* | B | |||

| 2149* | A | 3024 | B | 3335 | A | 3538 | A | 4060 | A | 4189* | A | 4306 | A | 4416 | A | |||

| 2152* | A | 3029 | A | 3336* | A | 3539* | A | 4061 | B | 4190 | A | 4307 | C | 4417 | A | |||

| 2153 | B | 3030 | A | 3337 | A | 3545* | A | 4062 | A | 4191* | A | 4308 | A | 4418 | B |